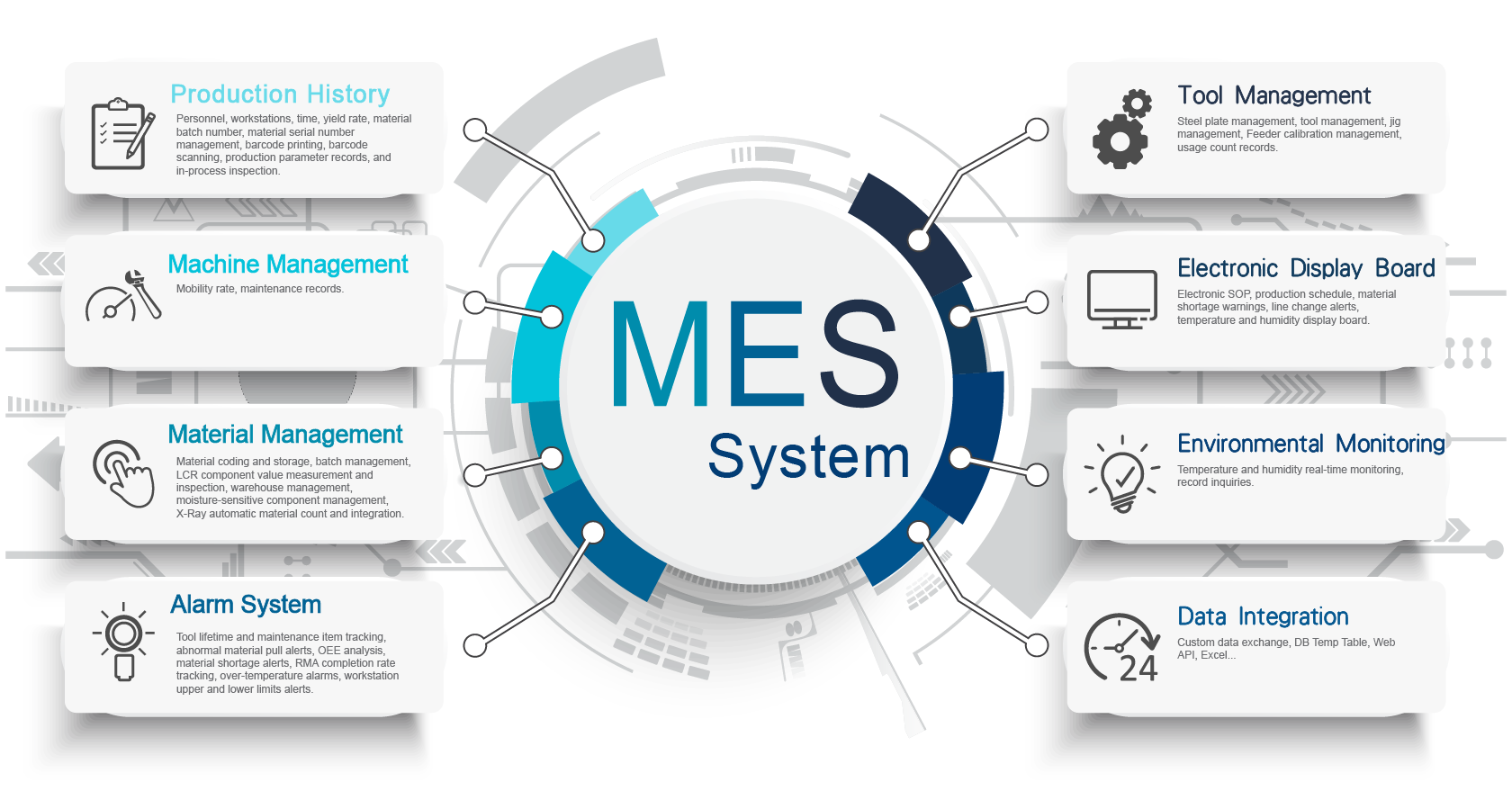

MES System

Production History

Personnel, workstation, time, yield rate, material usage records, key component management, serial number management, label printing on the production line, packaging and weighing, production parameter records, WIP inquiry

Machine Management

Utilization rate, maintenance records

Material Management

Reel number registration, reel merge/split management, LCR component value measurement records and alerts, warehouse management, moisture-sensitive component management, X-Ray automated inventory integration

Warning System

Work order production reminders, scrap abnormal warnings, production defect warnings, material shortage warnings, RMA repair progress alerts, over-temperature warnings, work order online prompts

Tooling Management

Stencil management, carrier management, solder paste management, feeder calibration management, usage records

Electronic Signage

Electronic SOP, production scheduling, material shortage warnings, scrap warnings, temperature and humidity signage

Environmental Monitoring

Real-time temperature and humidity control, record inquiry

Data Integration

Customized data exchange, DB Temp Table, Web API, Excel…

Production Efficiency Improvement

98

%

Shortened Manufacturing Cycle

10

%

Reduced Work-in-Progress

20

%

Improved Manufacturing Yield

99

%

Ying Yi Electronics: Enhanced SMT Manufacturing Through a Customized MES

Optimizing the SMT Workflow:

In Surface Mount Technology (SMT) manufacturing, a streamlined workflow from material procurement to shipment is critical. Manufacturing Execution Systems (MES) play a pivotal role in achieving this efficiency. Every step, from order management and material preparation to online equipment integration, contributes significantly to overall effectiveness.

Ying Yi's Tailored MES Solution:

Ying Yi Electronics offers a customized MES system designed to meet specific customer requirements, maximizing its applicability and practicality.

Real-Time Visibility and Control:

Following order placement, a series of online tracking processes, encompassing Bill of Materials (BOM) generation to final shipment, provides real-time access to crucial information. This allows for immediate identification of material shortages or production issues. Ying Yi's MES distinguishes itself through its high degree of customization, readily adapting to diverse scenarios and customer adjustments. Additionally, the system delivers real-time order status updates, enabling precise production management.

Comprehensive Manufacturing Support:

Ying Yi's MES encompasses four key areas: production management, quality control, equipment management, and external line tracking. Subcategories include solder paste management, stencil management (replacing "steel plate management"), FIFO (First-In-First-Out) inventory control, and baking management. The system's advantages are evident throughout the entire process, from BOM establishment to production traceability. Real-time monitoring of product yield and equipment utilization rates is facilitated. Furthermore, the MES ensures smooth production progress through continuous monitoring.

Beyond Monitoring: Traceability and Optimization:

Ying Yi's MES surpasses mere production monitoring. It empowers comprehensive tracking of each product's journey through the system, including BOM creation and production traceability. This enables real-time monitoring of product yield and equipment utilization rates, ultimately delivering the highest quality products to customers.

More: