What is SMT

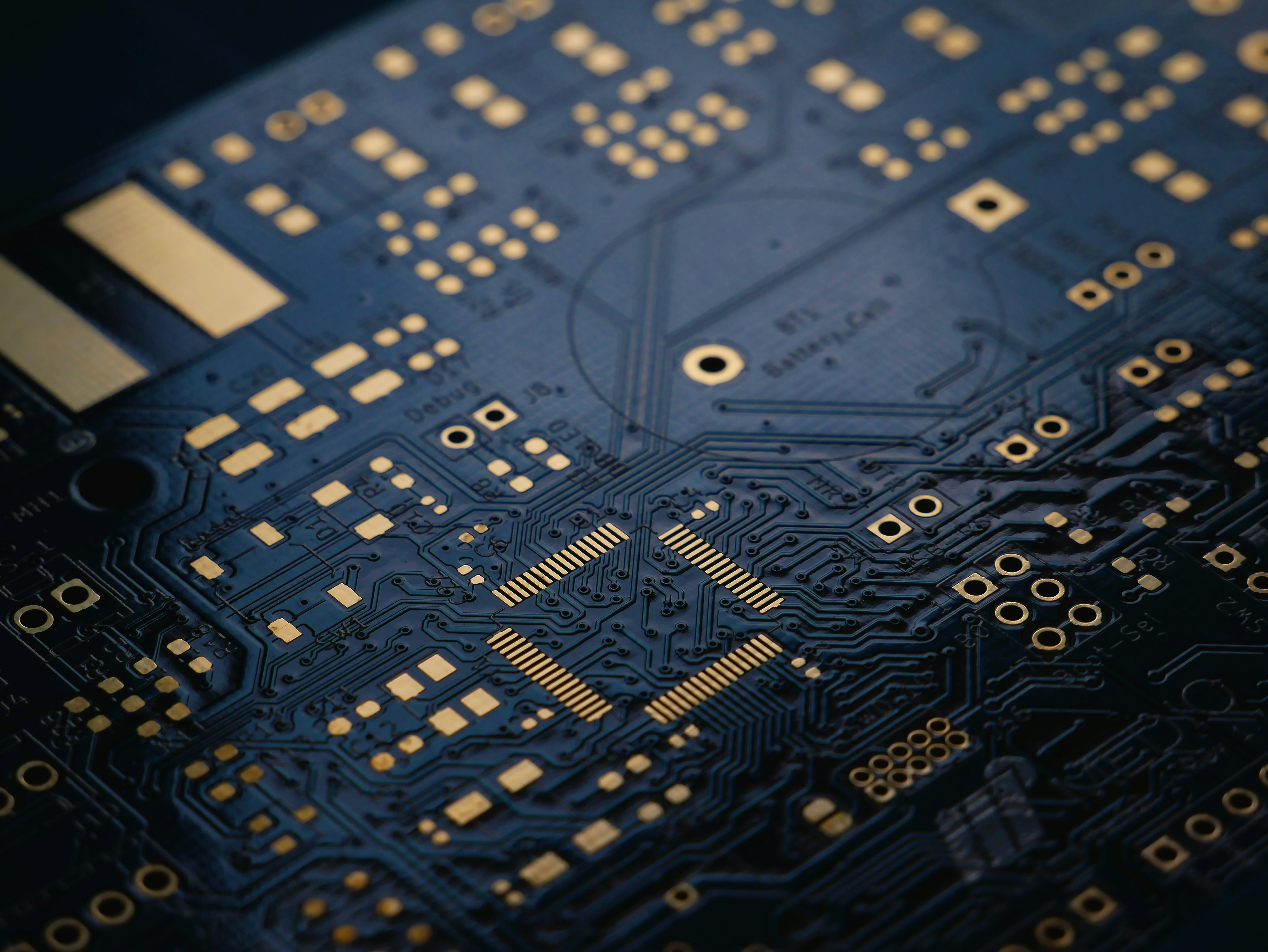

Surface Mount Technology (SMT) is a modern electronic manufacturing process used to assemble and solder surface mount devices (SMDs) onto printed circuit boards (PCBs). This manufacturing technique has replaced traditional through-hole component assembly methods, enabling miniaturization, efficiency, and high integration in electronic products.

Fundamental Principles:

The fundamental principle of SMT is to mount electronic components on the surface of a PCB using surface mount technology. These components include integrated circuits, resistors, capacitors, diodes, and a variety of others. Unlike traditional through-hole technology, SMT components have leads that connect directly to the PCB surface, eliminating the need for through-holes.

Key Advantages:

Space Efficiency: SMT technology allows components to be placed and soldered more densely on the PCB surface, increasing board space utilization and enabling smaller electronic devices.

Lightweight: SMT-built electronic components are lighter due to the absence of a large number of through-holes. This is particularly important in lightweight design and mobile devices.

Lightweight:

SMT-built electronic components are lighter due to the absence of a large number of through-holes. This is particularly important in lightweight design and mobile devices.

Production Efficiency:

SMT processes can typically be automated, increasing production efficiency. Robots and automated equipment can quickly and accurately place and solder components.

Performance Enhancement:

Due to the direct mounting of components on the surface, SMT technology helps to reduce inductance and resistance between components, improving circuit performance.

Application Areas:

SMT technology is widely used in various electronic products, including smartphones, tablets, digital cameras, computer hardware, communication equipment, and more. Its high integration and efficiency make it the mainstream technology for modern electronics manufacturing.

Conclusion:

SMT has revolutionized electronic manufacturing, bringing us more advanced, miniaturized, and efficient electronic products. As technology continues to evolve, SMT will continue to play a critical role in the electronics industry.